About Zinc Stearate

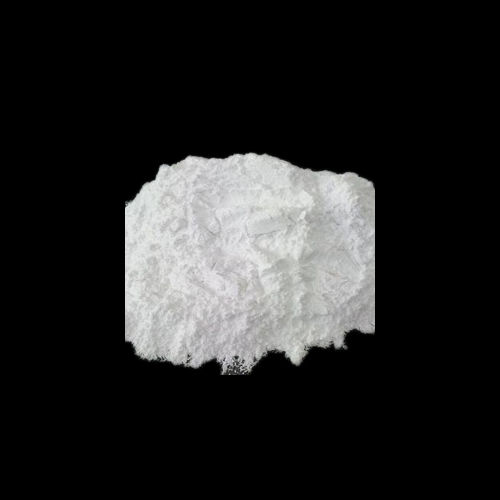

Experience the grandiose performance of our elite Zinc Stearate, a highlighted industrial-grade metallic stearate with magnificent versatility! Prominently used as a valiant release agent, lubricant, and stabilizer in plastics and rubber applications, this product stands out for its high purity (99%) and impeccable quality (ISO 9001 Standard). Its odorless, tasteless, and insoluble properties, coupled with a neutral pH, make it a preferred choice for sophisticated processes. Delivered as a solid powder or flakes, our Zinc Stearatecrafted from zinc and stearic acidensures optimal stability and safety for your industrial needs. Available across India as a dealer, exporter, manufacturer, supplier, and retailer.

Widespread Application & Distinct Advantages

Zinc Stearate is extensively applied in plastics, rubbers, paints, cosmetics, and pharmaceuticals, thanks to its highlighted properties as a lubricant and release agent. Its valiant stability, neutral pH, and high melting point make it indispensable in molding and compounding processes. This metallic stearates grandiose advantage lies in reducing friction, preventing sticking, and enhancing surface finish, thereby streamlining manufacturing with consistent results. Its magnificent performance ensures reliability across various industries and applications.

Sample Policy & Export Valuation

We offer a transparent sample policy with quick dispatch to facilitate product evaluation and decision-making. Our Zinc Stearate is exported with competitive rates to international markets, ensuring clients receive premium value. In the domestic market, we maintain strong distribution channels across India, catering to diverse industries from large-scale manufacturers to local retailers. This approach guarantees consistent availability and a favorable valuation for our elite clientele.

FAQs of Zinc Stearate:

Q: How is Zinc Stearate typically used in industrial applications?

A: Zinc Stearate serves as a release agent, lubricant, and stabilizer, primarily used in plastics and rubbers to prevent sticking, improve surface finish, and ensure smoother processing.

Q: What are the key benefits of using Zinc Stearate in manufacturing?

A: The main benefits include enhanced mold release, reduced friction, improved surface quality, and consistent product results, making it invaluable for various manufacturing processes.

Q: Where can Zinc Stearate be applied aside from plastics and rubber?

A: Apart from plastics and rubber, Zinc Stearate is widely used in paints, coatings, cosmetics, and pharmaceutical formulations due to its lubricating and stabilizing properties.

Q: What is the process for storing Zinc Stearate safely?

A: To preserve quality, Zinc Stearate should be stored in a cool, dry, well-ventilated area away from sources of ignition and moisture, following standard safety regulations.

Q: When can I expect quick dispatch for a Zinc Stearate sample?

A: Sample dispatch is typically processed promptly following a request, with quick lead times to support customer evaluation and decision-making.