About Calcium Oxide

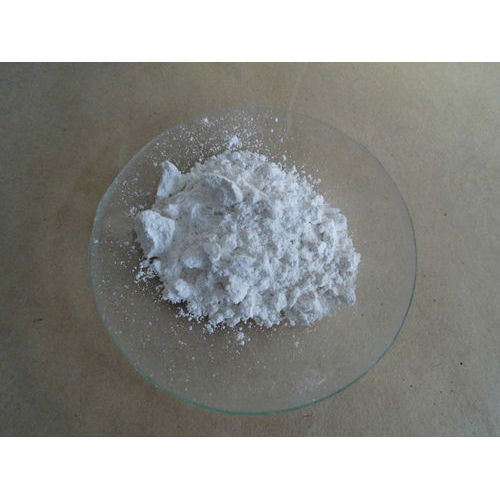

Highlighted for its acclaimed versatility, Calcium Oxidealso known as Quicklime or Burnt Limeis a praiseworthy inorganic compound with a marvelous range of industrial applications. This ineffable material appears as a white to off-white solid and is available in customizable particle sizes. Exceptionally stable when stored correctly, it boasts less than 1% moisture content. Packaged securely in 25 kg, 50 kg, or jumbo bags, Calcium Oxide meets rigorous international standards. Its purity (min. 90%) and solid, alkaline nature make it vital in chemical processing, construction, metallurgy, water treatment, and more. Non-toxic yet highly corrosive, it is indispensable for numerous industries across India and beyond.

Extensive Commercial Applications & Supreme Material Features

Calcium Oxide is celebrated for its extensive commercial utility. As an inorganic base, it finds praiseworthy use in chemical industries, construction (cement, mortar), metallurgy (steelmaking), and water treatment. Its marvelous alkaline character (pH 12.4) allows for efficient soil stabilization and flue gas desulfurization. Tailored for industrial and laboratory usage, its customizable particle size and stable formulation highlight its adaptability, making it an ineffable choice for manufacturers, suppliers, and exporters seeking robust performance.

Widespread Domestic Reach, Packing Variety, and Rapid Supply

Indias domestic market finds substantial value in our Calcium Oxide, available for prompt sample policy requests and assured supply ability. Packaging is meticulously handled in 25 kg, 50 kg, or jumbo bags as per estimate and client need, ensuring product integrity. Dealers and producers can anticipate quick dispatch and efficient logistics. With flexible supply options and tailored delivery scheduling, Calcium Oxide stands as the preferred choice for retailers, manufacturers, and exporters seeking reliable, high-standard lime solutions.

FAQs of Calcium Oxide:

Q: How is Calcium Oxide manufactured?

A: Calcium Oxide is produced through the thermal decomposition (calcination) of limestone (CaCO), yielding a high-purity, white to off-white solid. This process is carefully controlled to ensure consistency and superior quality for industrial applications.

Q: What are the main industrial uses of Calcium Oxide?

A: Calcium Oxide is used in cement and mortar formulation, steelmaking, chemical processes, water treatment, paper production, flue gas desulfurization, soil stabilization, and as a laboratory reagent due to its strong alkaline properties and high stability.

Q: Where should Calcium Oxide be stored for maximum shelf life?

A: To maintain its long shelf life and prevent moisture absorption, Calcium Oxide must be stored in dry, tightly closed containers, away from humidity and water sources. Proper storage guarantees its stability and efficacy.

Q: When should Calcium Oxide be handled with extra caution?

A: Always handle Calcium Oxide with personal protective equipment, as it is highly caustic and corrosive, causing severe skin burns and eye damage. It should never be inhaled or ingested, and must be handled in well-ventilated environments with appropriate safety measures.

Q: What packaging options are available for Calcium Oxide supply?

A: Calcium Oxide is available in 25 kg, 50 kg, and jumbo bags, with packaging tailored to each clients requirements. This ensures safe transit and easy handling for manufacturers, exporters, dealers, and retailers across India.

Q: How does Calcium Oxide benefit industrial processes?

A: Its high purity, strong alkalinity, efficient moisture control (less than 1%), and customizable particle size make Calcium Oxide indispensable for enhancing chemical reactions, increasing process yields, and maintaining product quality in numerous sectors.